Understanding Direct and Indirect Procurement

Procurement, on the surface, is all about getting the tools a company requires daily to run. Examining closely, you begin to include all the elements necessary for procurement to function: processing invoices, managing vendors, preventing fraud, handling payments, quality assurance, etc. Beyond appearances, it is rather more sophisticated than that.

Two neat slots separate procurement: direct and indirect. Although both are vital for every company to run, it’s crucial to know their roles so you can prioritize and give each the required focus. This will help you to handle procurement effectively, establish great supplier relationships, and guarantee a continuous supply of the inputs you need to keep your business going.

Direct Procurement

Direct procurement is the process of obtaining for your main business operations the commodities, materials, tools, and services you require. Basically, direct procurement is about obtaining those necessary goods and services with some processing that find their way immediately to your end users. It addresses the inputs that underpin everything your company provides.

Examples of Direct Procurement

Direct procurement consists in some instances in:

- A baker purchasing flour for bread

- A building company ordering cement and bricks for a continuous project

- A fabric manufacturer ordering textiles and cloth supplies for processing and eventual stitching down the line

Note: Direct procurement mainly finds application in physical manufacturing sectors where direct raw materials are transformed into tangible goods.

Indirect Procurement

Though in a non-essential capacity, indirect procurement—also known as indirect spend—deals with purchasing goods and services that complement the operations of a company. Among these indirect supplies include decorations, office supplies and stationery, etc. In their own right, indirect supplies remain absolutely vital for your company. They do not, however, directly contribute to the completed goods and services you present to your clients. Instead, they help to guarantee that the conversion of direct resources into completed products happens without any problems.

Examples of Indirect Procurement

Among the indirect supplies are:

- SaaS subscriptions—like Slack and Asana

- Employee development tools—books

- Workplace décor

- Office equipment including laptops and personal computers

In digital areas where there are no physical objects but rather largely provided services, indirect suppliers are increasingly evident.

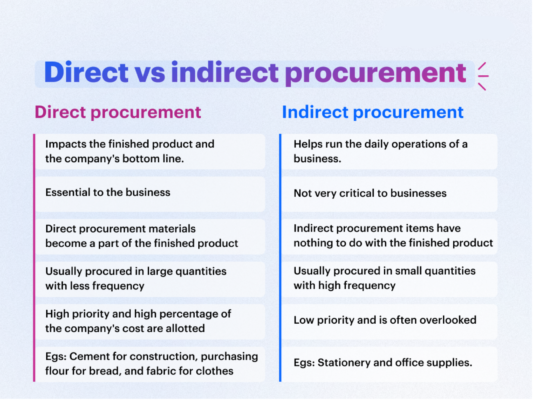

Direct vs Indirect Procurement: Differences

Direct and indirect procurement differ mostly in their addressed function. Whereas indirect procurement deals with the supply of spontaneous goods, direct procurement concentrates on ensuring the key supplies that are handled and provided to your clients. The varied purposes of direct and indirect procurement imply variations in their operations. You must so gently change your approach to both branches to get them perfect.

Focus on Client-Vendor Relationship

Direct procurement deals with obtaining the materials that form the foundation of what your company provides for clients. That is, without the direct procurement products, nothing works. Building long-term, sustainable connections with your suppliers can help you to assure yourself of a consistent supply chain. Vendor management, contracts, minimum order amounts, etc., have use here as well.

Direct procurement calls for the development of a strong customer-vendor connection that can remain resilient when needed, so offering security for both parties. Making a strategic sourcing plan helps to strengthen the buyer-vendor relationship rather nicely. Here’s a how-to for it.

Conversely, the indirect procurement deals with non-essential products that support your company operations but do not form part of your main business activity. As such, indirect procurement lacks the focus direct procurement enjoys. Instead, your company might have a vendor shortlist and apply the services as needed. You have plenty of options even if they fall short when demanded, and you can even postpone the purchases of the items you intend to obtain.

Given its significance, direct procurement results in closer vendor relationships you can rely on; indirect vendors can be handled with little to no effort to keep their services for the long run. Too many indirect supplies are often rather small to offset the expenses of locking into agreements, etc.

Planned as Opposed to Unplanned Expenditure

Direct procurement controls the basic supplies your company requires daily, hence it is important to give resilience top priority. To prevent interruptions to your supply chain, the necessary inputs you must keep running operations must be adequately planned and budgeted well in advance.

Conversely, for indirect supplies, it might be difficult to project demand and so, little planning or budgeting for indirect procurement exists. Unlike direct supply, indirect supplies are often acquired organically as the demand develops.

Managing Inventory

Inventories management addresses acquisition, storage, and planning for inventories. Given the risk and profit involved in controlling the supply chain for your direct inputs, most usually this is limited to direct supplies. Indirect inputs are generally not planned for, hence there is no long-term approach for controlling them.